What is PTC?

A PTC, or semiconductor, is a ceramic-based electrical component with temperature-dependent resistance that is used as a heating element. Its positive temperature coefficient allows electrical current to flow better at low temperatures than at high temperatures. As the temperature rises, the PTC’s natural resistance increases while its current conductivity and power output decrease until a state of equilibrium is reached and the current can barely flow anymore. That’s the so-called PTC effect. Thanks to their self-regulating characteristic, PTC heating elements cannot overheat, which makes this heating technology particularly safe and reliable.

Characteristic PTC Curve

The typical resistance curve of a semiconductor as a function of temperature is called PTC curve. The initial resistance of the PTC first decreases slightly with increasing temperature until the lowest resistance value Rmin is reached. Now the actual PTC behavior begins as the resistance increases non-linearly up to the nominal temperature Tc. At this point, also known as Curie temperature, the PTC’s resistance increases significantly. The operating range of the PTC extends from the nominal temperature Tc to the maximum final temperature Te, where hardly any current flows. The maximum temperature of a PTC depends on its ceramic composition and can therefore be determined in advance. Another characteristic of the PTC is its inrush current. As the resistance of the PTC is at its lowest value in Rmin, a particularly large amount of current can flow there, causing it to undergo an increased inrush current for a few seconds each time it is switched on.

680

PTC Types

25

Watts per cm²

1200

Volt

240

Degree Celcius

PTC Characteristics

Multi-voltage capability

Due to the PTC effect and the resulting variable resistance, semiconductors are multi-voltage capable in a defined range. For example, most PTC heaters can be operated at 230 V as well as at 400 V without any significant change in power.

Dynamic power adaptation

The power output of a PTC heating element depends on the heat extraction. If a lot of heat is extracted from the semiconductor, it automatically readjusts its temperature and increases its power. As soon as it reaches its maximum temperature, the power decreases again and hardly any current flows. This dynamic power adjustment makes PTC heating elements especially energy-efficient.

Self-limiting effect

Due to the logarithmic increase of the PTC's natural resistance in relation to the temperature, the PTC limits itself. As soon as the maximum temperature is reached, the semiconductor becomes non-conductive and settles due to the physical effect. Thanks to this effect, PTCs are particularly safe and do not require any additional thermal fuse.

Inrush current

PTC heaters experience an increased inrush current for a few seconds each time they are switched on. We therefore recommend to use a time-delay fuse in order to protect the application.

Current load for low voltage applications

For low voltage applications, the currents are much higher than for household applications (230 V) due to Ohm's law. Therefore, it is important to ensure a sufficiently large wire cross-section.

Power strongly dependent on PTC temperature

The power of a PTC heater is dependent on two factors: the temperature difference dT and the heat dissipating surface A. This relationship is described by the formula P = α * A * (dT), where α stands for the heat transfer coefficient. For an air heater, dT would be the temperature difference between the air and the surface of the heater.

Higher PTC temperatures (dT) allow for higher power outputs. For most applications, however, a temperature between 180 °C and 240 °C is recommended.

Increasing the heat dissipating surface area can also increase performance.

Customer application testing

When using PTC heating elements, we always recommend to run several application tests in order to confirm the correct and reliable function of the PTC heater using appropriate measurements.

PTC Applications

Heating solutions for trains, railways and switches

PTC heaters are perfectly suited for railway applications. With a limited temperature below 200°C, they are easier to handle according to fire protection standards and can also compensate for voltage fluctuations without a significant change in heating power.

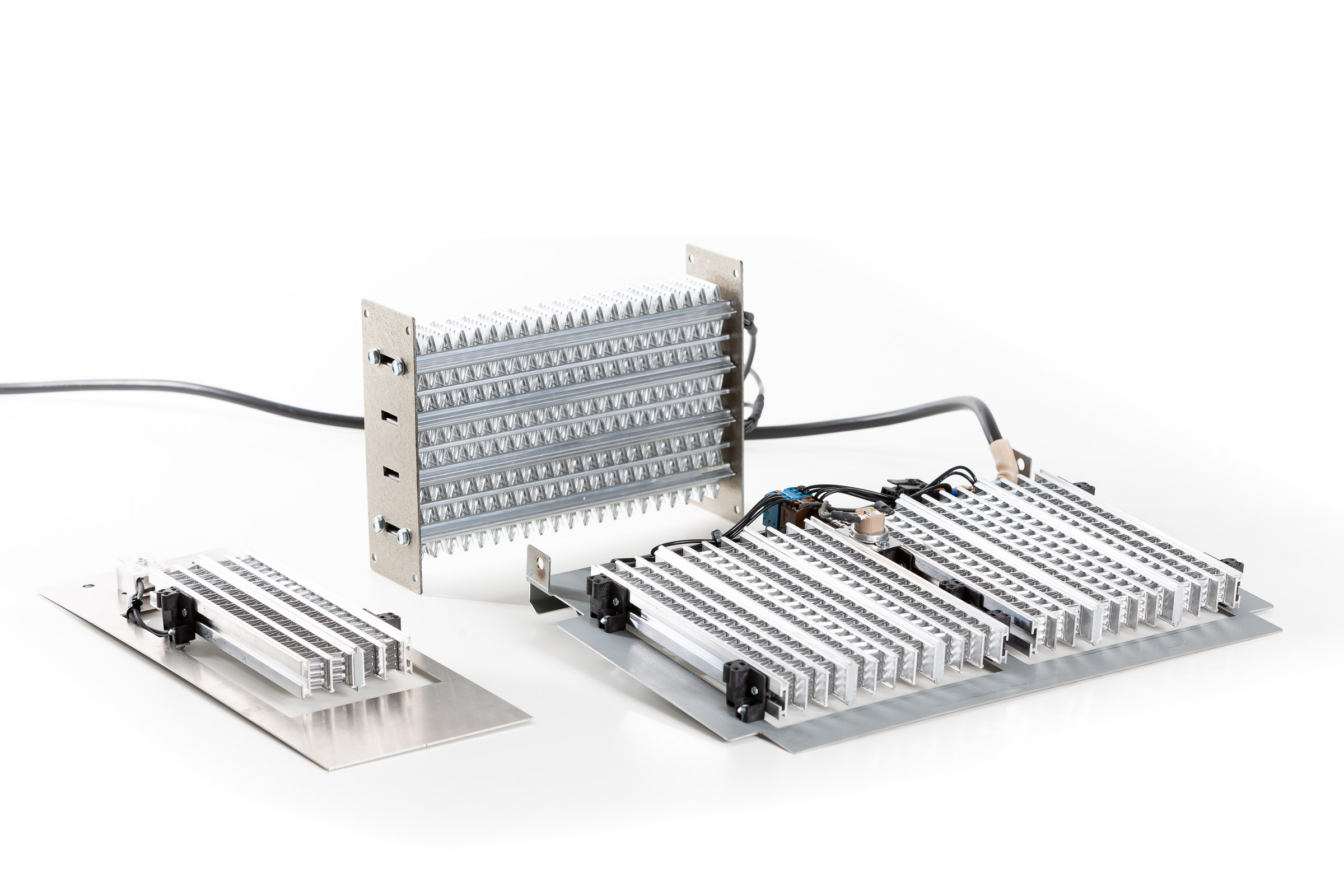

Pre-heater for heat exchangers in HVAC systems

Insulated PTC Air Heaters (HRP) were specially developed for use in ventilation systems. Thanks to their modular design, they can adapt to the cross-section of customers’ ventilation ducts, while also featuring a low pressure drop thanks to their delta-shaped fins. Low radiation and low temperature overshoot in case of failure make them also eligible for usage in EPP/EPS housings.

Convection heater for

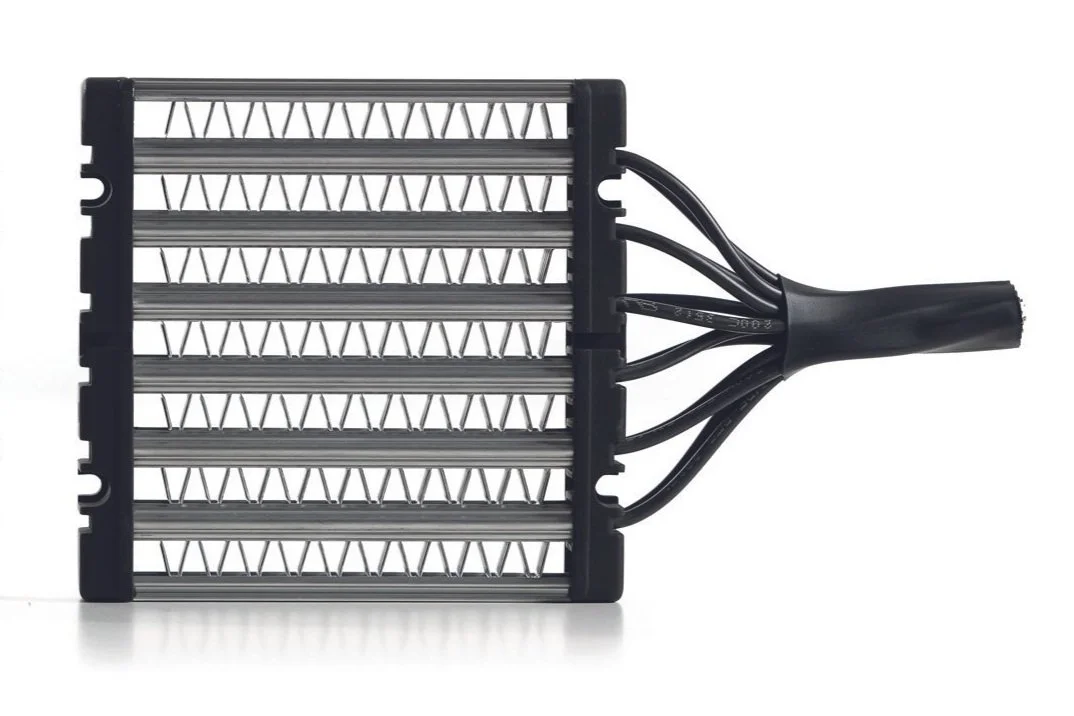

control cabinets and electrical enclosures

The combination of PTC effect and an thermally optimized aluminum profile makes the perfect convection heater. Depending on the outside temperature, the heater dynamically adjusts its power in order to protect components in electrical enclosures from frost and moisture. With the help of thermal simulations, a highly efficient aluminum profile has been developed which achieves high performance despite its compact and slim design.